Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Providing our customers with the highest quality products, competitively priced, with a level of custom made service our customers’ expectations.

Focusing on the production, manufacturing, and wholesale of power transmission belts for precision mechanical equipment

Our company specializes in producing rubber synchronous belts, PU synchronous belts, agricultural machinery belts, triangular belts, multi wedge belts, V-belts, open belts, and various transmission belt products that meet ISO national standards.Company produces up to 8 million synchronous belts throughout the year, with highly competitive prices. The inventory of different models and specifications of transmission belts is sufficient to meet the needs of most customers, while supporting processing and customization.We have advanced production inspection equipment and a scientific quality management system, and our products are widely used in various industries such as food machinery, weaving machinery, CNC machine tools, printing and packaging machinery, automobile manufacturing, industrial machinery, and so on. Huanball has become a designated …...

With over 10 years of industry experience, professional knowledge, high-quality products, and thoughtful services, we aim to gain the trust of advertising users.

We produce up to 5000000 transmission belts throughout the year, providing all brands and specifications of transmission belt products on the market.

We produce transmission belts that meet ISO national standards and undergo quality supervision and inspection, making us your reliable partner.

We have a history of over 15 years in the production and manufacturing of power transmission belts, and we also have extensive experience in trade exports.

We will provide professional customized services based on the brand, model and other product parameters provided by the customer.

We are factory direct sales, eliminating the overlap of intermediate trade, and the price is definitely the most favorable under the same product quality.

If you have any questions,please feel free to contact customer service or send us an email.Pre sales and after-sales service will be provided until you are satisfied.

Huanbo will provide various standards and high-quality transmission belt to meet the requirements of specific customers.

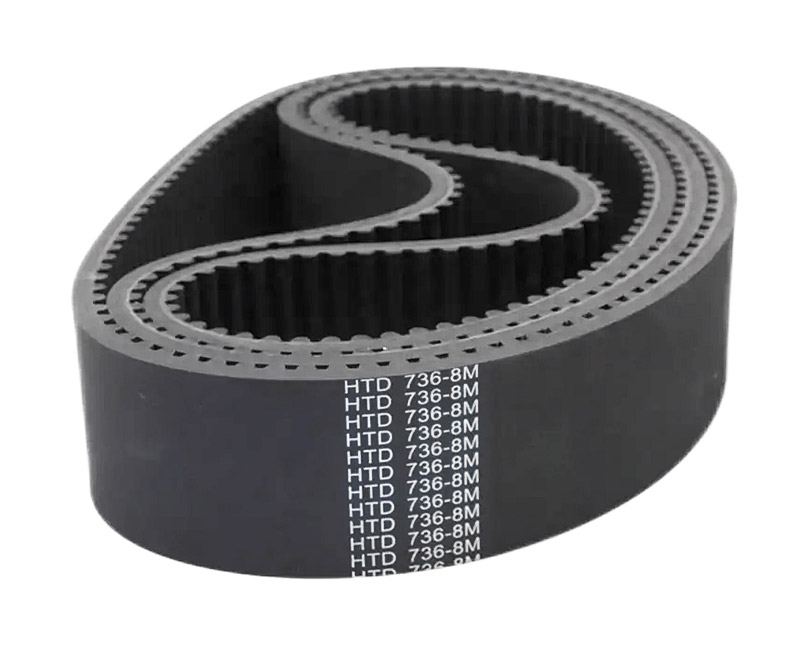

Customize various types of rubber timing belts

Factory direct sales of double-sided toothed synchronous belts

Wholesale automotive engine synchronous belts

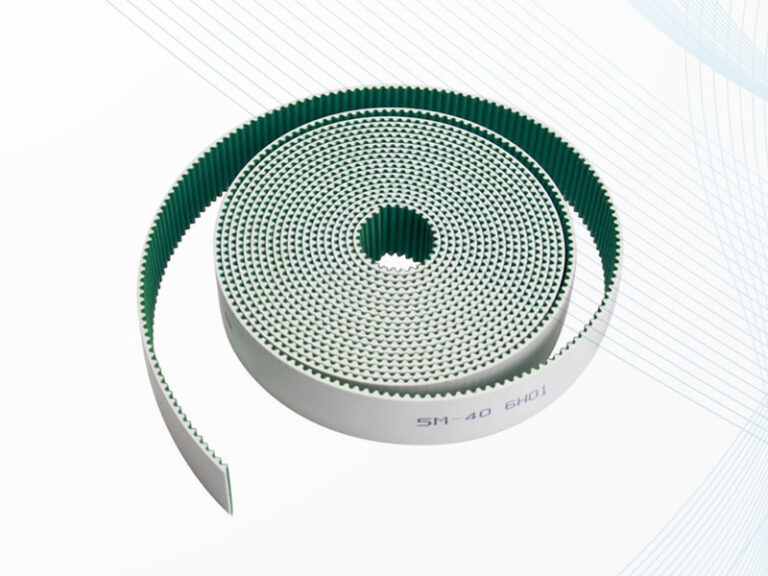

High quality polyurethane PU open-endde synchronous belts

Synchronous belt is a toothed transmission belt mainly made of materials such as rubber and steel wire rope. As an efficient transmission method, it is widely used in various mechanical equipment. It has the advantages of simple structure, stable operation, and convenient maintenance. By using synchronous belts, the continuity and efficiency of the production process can be achieved, and production efficiency and quality can be improved. And then meet the production needs of different industries.

Applied in the transmission system of key components such as automotive engines, it can withstand working conditions of high temperature, high speed, and high load, with high transmission efficiency, low noise, and less prone to wear and looseness.

Lorem ipsum dolor sit amet, consectetur adipiscing elThe synchronous belt in textile machinery equipment is widely used in textile production lines, achieving precise synchronization of the movement of various components in a high-speed operating environment to ensure the quality and texture of the fabric.it. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Mainly used in food processing, packaging, and warehousing, to achieve continuous production and transportation of food, improve production efficiency, and ensure the quality and safety of food.

Applied to transmission paper, adjust printing position, and control the rotation speed of printing plates, achieving precise paper positioning and printing position adjustment, thereby improving printing quality and efficiency.

Used in drug production and medical devices, automated production and transmission of drugs and medical devices are achieved through the use of synchronous belt conveyors, improving production efficiency and quality.

The raw rubber is masticated using an open mill to transform the raw rubber from a highly elastic state to a plastic state to reduce the elasticity of the raw rubber and improve its plasticity.

Mixing is an important process in the production process of rubber timing belts. By uniformly mixing the plasticized raw rubber and compounding agents, the temperature and time are controlled during the mixing process to improve the performance of the rubber compound.

The production process of rubber timing belt is very important, which is directly related to the quality and performance of the product.By using various technological means, including mastication, mixing, molding, vulcanization and other processes, during the production process, it is necessary to control the parameters of each link to ensure the production of rubber timing belt products that meet the needs of our customers.

The rubber material is pressed into strips or other shapes using a calender. During the molding process, the pressure and temperature need to be controlled to ensure that the size and shape of the timing belt meet the requirements.

Vulcanization is one of the most important processes in the synchronous belt production process. It mainly puts the formed synchronous belt into a vulcanization box for heating treatment to convert plastic rubber into elastic rubber in order to obtain ideal performance and long service life.

When inspecting rubber synchronous belts, it is necessary to refer to relevant industry standards (ISO standards, GB standards) and conduct strict quality inspections, which mainly involve the shape, size, tensile strength, wear resistance inspection, etc. of the synchronous belts. The purpose is to Guarantee the quality and performance of rubber timing belts.